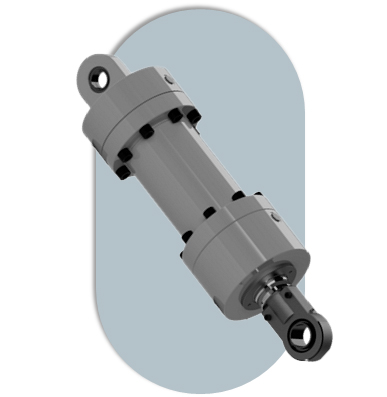

Mill-duty hydraulic cylinders are heavy-duty components designed for the most demanding industrial applications, particularly in steel mills, metal processing, and heavy manufacturing environments. These cylinders are engineered to withstand extreme conditions and provide reliable, high-force performance.

Mill-duty hydraulic cylinders are constructed with robust materials, often featuring high-strength alloy steel, to withstand heavy loads, high pressures, and harsh operating environments.

These cylinders are characterized by large bore sizes, enabling them to generate substantial force for applications that require significant power, such as metal forming and heavy equipment lifting.

Designed for continuous and intense use, mill-duty cylinders undergo stringent manufacturing processes to ensure durability under extreme conditions, including exposure to heat, dust, and heavy vibrations.

Manufacturers offer customization options to tailor mill-duty cylinders for specific applications. This may include adjusting bore and rod sizes, stroke lengths, and other parameters to meet the unique requirements of heavy-duty operations.

Mill-duty cylinders are built to handle high-pressure hydraulic systems, providing the force required for heavy lifting, pressing, or other challenging tasks commonly encountered in industrial settings.

Equipped with advanced sealing technologies, such as lip seals and heavy-duty wipers, to prevent contamination and ensure reliable performance in environments with particulate matter and debris.

Mill-duty cylinders may feature tie-rod or welded construction, offering flexibility to match the specific needs of different applications. Tie-rod designs provide modularity, while welded constructions enhance overall strength and rigidity.

These cylinders are commonly integrated into heavy machinery, such as rolling mills, forging presses, and metal forming equipment, where their rugged design and high-force capabilities are crucial.

Manufacturers often employ coatings or materials with corrosion-resistant properties to protect mill-duty cylinders from the corrosive effects of certain industrial processes.

Despite their heavy-duty nature, mill-duty cylinders can be engineered to provide precise control and movement, ensuring accuracy in applications where precision is essential.

In summary, mill-duty hydraulic cylinders are designed for the toughest industrial environments, where heavy loads, high pressures, and harsh conditions are the norm. Their robust construction, customization options, and ability to deliver high-force performance make them indispensable for critical applications in heavy manufacturing and metal processing industries.

To guarantee the reliability of the product, Bicelli Geco carries out its hydraulic cylinders internally, from beginning to end. Starting from the study of the project, till after-sales service.