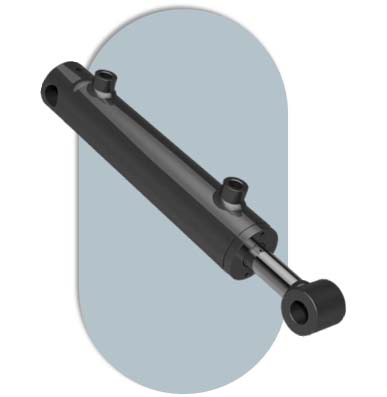

Welded hydraulic cylinders are essential components in hydraulic systems, serving a crucial role in converting fluid power into mechanical force. These cylinders are characterized by their robust construction, where the cylinder tube is welded directly to the end caps, creating a sturdy and leak-resistant structure.

Welded hydraulic cylinders are typically constructed from high-strength steel, ensuring durability and resistance to the forces generated in hydraulic applications.

The welding process used in their fabrication creates a seamless and continuous structure, minimizing the risk of leaks and providing enhanced structural integrity.

These cylinders find widespread use in various industries, including construction, agriculture, manufacturing, and material handling, where reliable and efficient hydraulic systems are essential.

The welded design allows for a more compact and space-efficient cylinder, making them suitable for applications with limited space constraints.

Manufacturers often offer customization options for welded hydraulic cylinders, allowing users to choose specifications such as stroke length, bore size, and rod diameter to meet specific application requirements.

Welded cylinders are often considered cost-effective compared to other types of hydraulic cylinders. The simplicity of their design and manufacturing process contributes to their affordability.

Due to their robust construction, welded hydraulic cylinders generally require minimal maintenance. This makes them a preferred choice for applications where reliability and long service life are crucial.

Welded hydraulic cylinders are available in both single-acting and double-acting configurations, providing flexibility for different hydraulic system designs.

These cylinders are equipped with various sealing options to prevent fluid leakage and ensure efficient operation. Common seals include O-rings and U-cups.

The welded design, when properly sealed, helps prevent hydraulic fluid leakage, contributing to environmental sustainability by minimizing the risk of contamination. In summary, welded hydraulic cylinders play a vital role in hydraulic systems, offering a durable, cost-effective, and space-efficient solution for converting hydraulic energy into mechanical force. Their versatility and reliability make them indispensable in a wide range of industrial applications.

To guarantee the reliability of the product, Bicelli Geco carries out its hydraulic cylinders internally, from beginning to end. Starting from the study of the project, till after-sales service.